{“@context”:”http:\/\/schema.org\/”,”@id”:”https:\/\/johnchow.com\/bugatti-tourbillon-what-a-9000-rpm-v16-sounds-like\/#arve-youtube-p2zhcrl_vl4-2″,”type”:”VideoObject”,”embedURL”:”https:\/\/www.youtube-nocookie.com\/embed\/p2zHCrL_vL4?feature=oembed&iv_load_policy=3&modestbranding=1&rel=0&autohide=1&playsinline=0&autoplay=0″}

Turn up the volume and enjoy the sound of an 1,800 hp V16 revving all the way to 9,000 RPM! The new Bugatti Tourbillon is the successor to the Veyron and the Chiron. It packs 1,800 hp and is incredibly fast, with a top speed of 276 mph. It is also capable of 0-62mph in 2 seconds, 0-124 mph in under 5 seconds, 0-186 mph in under 10s seconds and 0-248 mph in under 25 seconds.

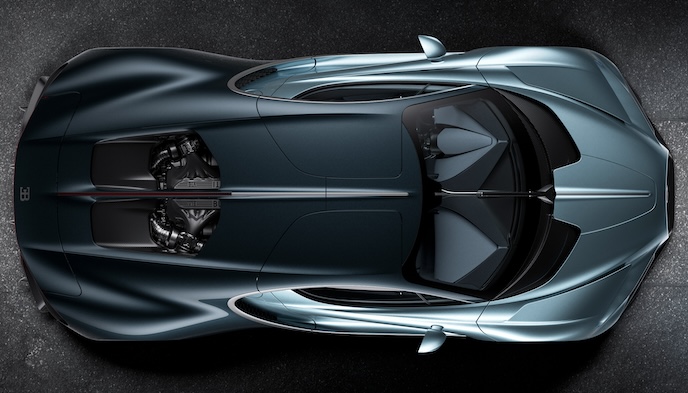

In 2004, the reborn Bugatti brand transformed the world of automotive performance and luxury with a 1,001 hp hyper sports car: the Veyron. The first road car with more than 1,000 hp was succeeded in 2016 by another engineering feat so ambitious it reset all expectations of performance, the world’s first 1,500 hp car: the Chiron. At the heart of these cars was the world’s most advanced automotive engine: an 8.0-liter quad-turbo W16. Now, 20 years after Bugatti invented the hyper sports car, it redefines the concept completely with an entirely new powertrain and platform. This is the Bugatti Tourbillon.

The next-generation Bugatti hyper sports car is powered by an all-new 8.3-liter naturally aspirated V16 engine – engineered with the help of Cosworth – paired with a front e-Axle with two electric motors and one electric motor mounted at the rear axle. In total, the Tourbillon produces 1,800 hp with 1,000 from the combustion engine itself and 800 hp from the electric motors. It’s an extraordinary achievement – delivered thanks to a host of cutting-edge materials and technology – given the Veyron achieved 1,001 hp from its 8.0- liter capacity engine with four turbochargers, and the new V16 is completely naturally aspirated. Constructed from lightweight materials, the engine weighs just 252 kg.

Ever since car manufacturers began to embrace digital screens and touchscreens in cars, the rate of progress has been so rapid that within less than a decade, the technology appears outdated. Imagining the Tourbillon on concours d’elegance lawns not just in 10 years but perhaps in 100 years, the design philosophy of the interior focused on timelessness. Inspired by the world of horologie, in which wristwatches over 100 years old can still be worn and used today, integrated into modern fashion and lifestyles seamlessly, the design and engineering teams pioneered an authentic analogue experience in the cabin.

The centerpiece of this takes the horologie philosophy to its most literal conclusion; an instrument cluster designed and built with the expertise of Swiss watchmakers. Made up of more than 600 parts and constructed from titanium as well as gemstones such as sapphire and ruby, the skeletonized cluster is built to the largest tolerance of 50 microns, with the smallest at 5 microns, and weighs just 700g. This intricately engineered masterpiece remains a focal point of the driving experience, fixed in place as the rim of the steering wheel rotates around it – a set-up known as a fixed hub steering wheel. Through this ingenious concept Tourbillon drivers have an unobstructed view of their instrumentation independent of the steering angle because the spokes reach around the back of the instrument cluster

The center console is a blend of crystal glass and aluminum, revealing the intricate workings of the switches and the engine start ‘pull’ lever that it hosts. This glass was developed over 13 separate stages to ensure it was both perfectly clear and extremely strong and safe in the event of an accident. The aluminum parts of the console are anodized and milled from a single block of metal, while the knurled aluminum switches sit at the head of a complex mechanism that is fully visible beneath the crystal glass – entirely developed in-house. The act of igniting the all-new naturally aspirated V16 engine and electric powertrain has been crafted to be a physical experience, a nod to the rituals of historic automobiles – a pull to start and a push to cease.

But hidden from view until desired is a high-definition digital screen, which displays vehicle data and offers seamless mobile connection. An intricately engineered mechanism deploys the touchscreen from the top of the center console; portrait mode for the reversing camera in just two seconds and full landscape mode in five seconds.

The electric motors are powered by a 25 kWh oil-cooled 800V battery housed in the central tunnel and behind the passengers. With four-wheel-drive and full torque-vectoring, it offers ultimate traction and agility. The front e-axle houses two electric motors, with a further motor on the rear axle, for a total of 800 hp from the electric powertrain system. The electric powertrain, with the electric motors spinning up to 24,000 RPM and a fully integrated dual silicon-carbide inverter, is amongst the most power-dense in the world. The e-axles are delivering over 6 kW per kg of e-axle mass, including inverters, motors and gearboxes. While power, throttle response and torque-fill are priorities for the electric powertrain, the relatively large energy content of 25 kWh allows for a very usable all- electric range of more than 60 km / 37 miles.

The structure is made from a next-generation T800 carbon composite, which incorporates a number of weight-saving innovations, such as integrating the battery as a structural part of the monocoque and an unprecedented crash composite rear diffuser, inspired by top level motorsport. The front composite airducts that flow through the front of the car are also integral to the structure, ensuring that each and every part of the rigid, lightweight structure is optimized. For example, the front and rear frames exhibit low pressure thin wall aluminum casting and 3D printed structural braces, contributing to a structure that is significantly lighter and stiffer than its predecessor!

The completely new chassis integrates multi-link suspension front and rear, forged from aluminum, moving on from the double wishbone steel construction found in the Chiron. By opting for a new organic-designed suspension arm and upright, 3D-printed in aluminum, engineers have saved 45% in suspension weight compared with the Chiron. The rear also features an AI-developed 3D-printed hollow airfoil arm to enhance vehicle dynamics and aerodynamic performance.

The brakes are equally advanced, featuring the ultimate carboceramic technology. A bespoke brake-by-wire system is introduced, fully integrated with the moveable pedal box, and blended seamlessly through an integrated vehicle non-linear controller developed by Bugatti to the hybrid powertrain. Michelin Pilot Cup Sport 2 tires – 285/35 R20 at the front and 345/30 R21 at the rear – are a bespoke development for the Tourbillon.

Within the new chassis, the new ultra compact and lightweight front e-axle with dual independent motors, including the dual-inverter, fits within the same package space that was available in Chiron, adding more complexity without requiring more space. Designers and engineers also freed up more storage space and a larger luggage component, as part of the clean-sheet chassis and bodyshell design, allowing owners to fit a set of bespoke Bugatti Tourbillon luggage.